Ambitious investments for all activity sectors

In September 2022, TotalEnergies launched a plan to accelerate energy efficiency improvements at its sites worldwide. The Company is investing $1 billion over the 2023-2025 period to reduce energy consumption and cut greenhouse gas emissions by 2 Mt CO2e. This plan has enabled us to accelerate the actions undertaken for several years in the Company’s operating sectors. At end-2024, these investments already amounted to some $750 million. They have reduced emissions by around 1.5 Mt CO2e/year and generated energy savings of over $100 million a year. Taking into account the efficiency projects reported by the teams at the industrial sites, a second energy efficiency improvement plan will be rolled out over the 2026-2028 period with a further $1 billion investment.

Focus on three practical cases

1Shutting down certain underused gas turbines

At hydrocarbon extraction sites, some of the gas produced by oil reservoirs is used in gas turbines to generate the electrical power needed for equipment such as water injection pumps and treatment units. TotalEnergies has launched a project to shut down certain underused gas turbines on its operated assets. Since 2021, 74% of Exploration & Production assets have been optimized in this way, enabling a total of nine gas turbines to be shut down. This initiative has resulted in GHG savings of around 130 kt CO2e/year, while reducing maintenance costs and recovering additional gas. In 2024, in Angola, two gas turbines were shut down on Block 17 (Dalia and Pazflor), reducing CO2 emissions by 29 kt CO2e/year and saving 13 Mm3/year of fuel gas (see also SN#76, At the heart of our businesses), while in the United Kingdom, the Elgin site reduced its CO2e emissions by 15 kt CO2e/year by switching from two turbines to one.

2Optimizing heat exchangers at Refining & Chemicals sites

In Le Havre, France, the modernization of the equipment in the reforming unit, including the furnace, an exchanger and a column, has resulted in a reduction of 75 kt CO2e/year. In addition, a heat recovery project has also been implemented. The waste heat emitted by the refinery process will be used to supply the district heating network for the city of Le Havre, with an associated reduction of 18 kt CO2e.

More broadly, improving energy efficiency at Refining & Chemicals platforms involves optimizing heat exchangers, furnaces and the steam network. For example, at our operated sites, the performance of furnaces has been improved by perfecting combustion conditions, which has led to a reduction in the associated GHG emissions.

3Improving the efficiency and performance of combined-cycle power plants

In 2024, at the Pont-sur-Sambre combined-cycle power plant (CCGT) in the Nord department of France, major modifications were made to the gas turbine during a major maintenance shutdown. The same project is planned for the St Avold CCGT (Moselle, France) in 2025. Over a large part of the power station fleet, high-power electric motors have been replaced by the latest-generation motors with variable speed drives, which are more efficient.

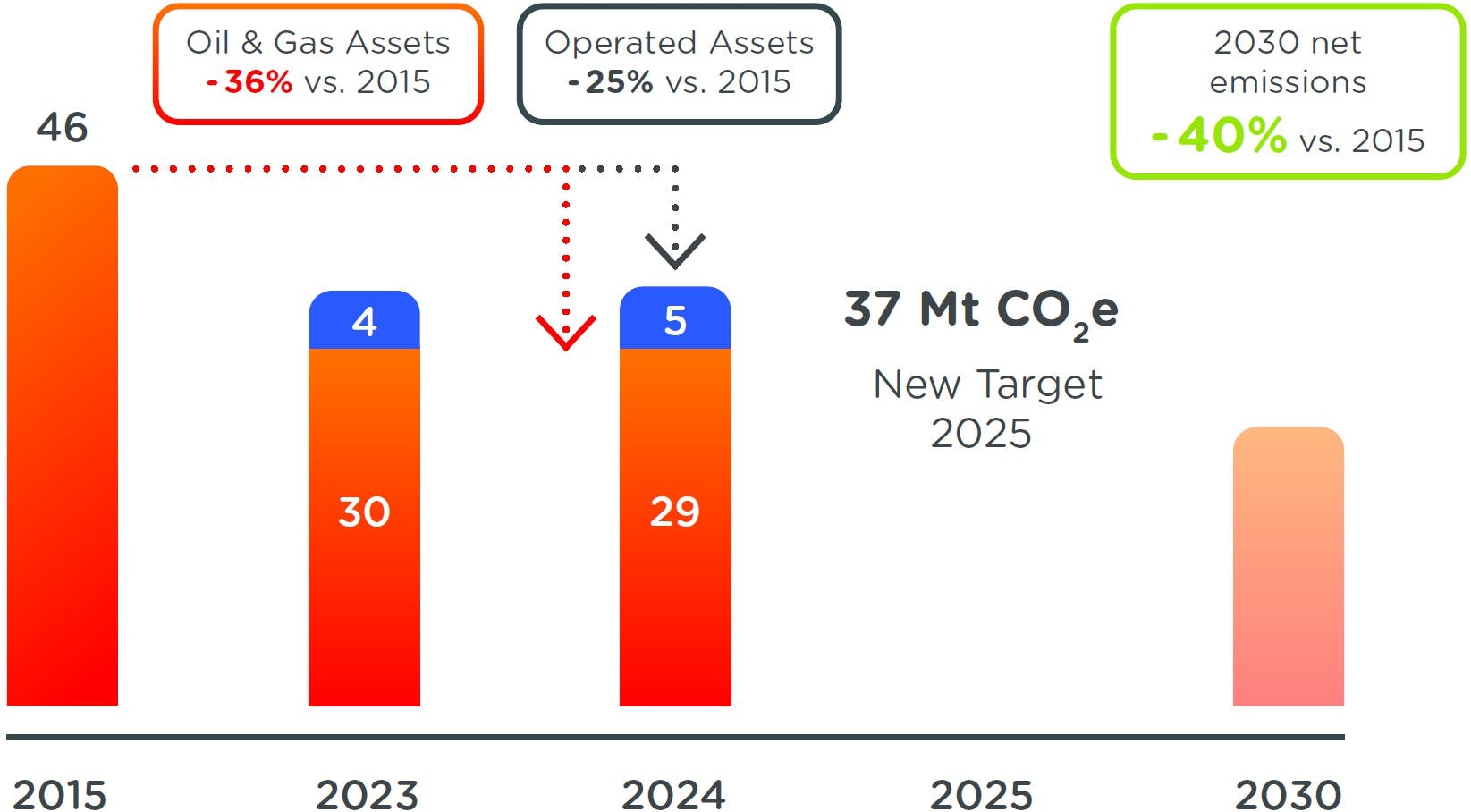

Scope 1+2 emissions of operated facilities (Mt CO2e)

Scope 1+2 emissions from operated facilities (in Mt CO2e)

Emissions change between 2015 and 2030:

2015

- Total : 46 Mt CO2e

- Breakdown: from Oil & Gas assets only

2023

Total : 34 Mt CO2e, broken down as follows:

- 30 Mt from Oil & Gas assets

- 4 Mt from gas-fired power plants (CCGT)

Observed reduction:

- 36 % for Oil & Gas assets (vs. 2015)

- 25 % for all operated facilities (vs. 2015)

2024

Total: 34 Mt CO2e, broken down as follows:

- 29 Mt from Oil & Gas assets

- 5 Mt from CCGT

Short-term target:

- 37 Mt CO2e for 2025

2030 (target)

- Expected net emissions: -40% compared to 2015

- Estimated visual level of around 27 to 28 Mt CO2e

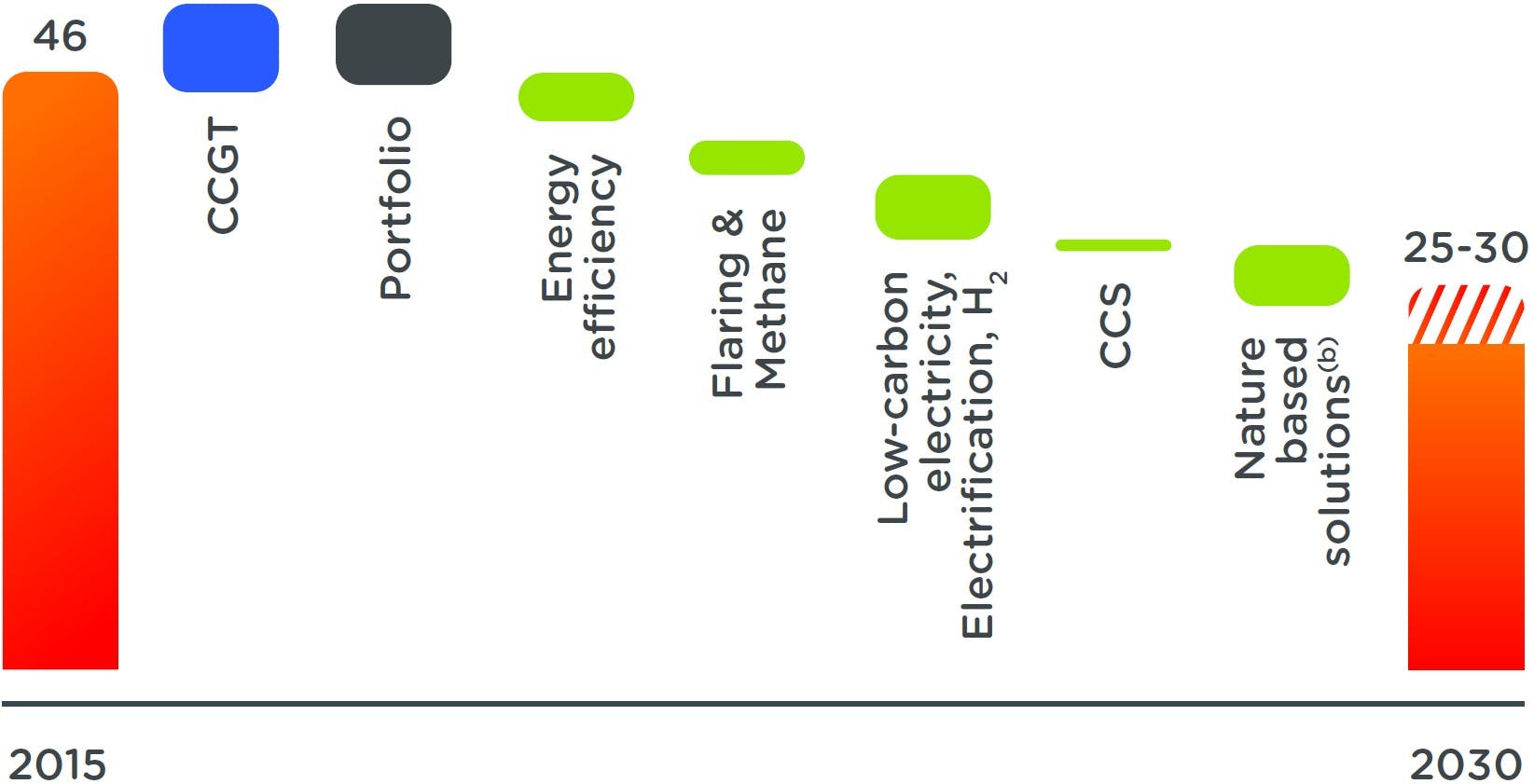

Scope 1+2 from operated facilities: levers to reach our -40% target in 2030(a) (Mt CO2e)

Scope 1+2 of operated facilities: levers to achieve the -40% target by 2030

(expressed in Mt CO2e).

Target:

Reduction of emissions from 46 Mt CO2e in 2015 to 25-30 Mt CO2e in 2030.

Main levers for action identified:

- Portfolio

- Energy efficiency

- Flaring & methane

- Low-carbon electricity & electrification/hydrogen

- CCS (Carbon capture and storage)

- Nature-based carbon sinks (b)